Structural features

1.Safe and long-life structure: In strict accordance with international standards, the requirements of pressure piping such as corrosion allowance, wall thickness and standard piping diameter are fully considered.

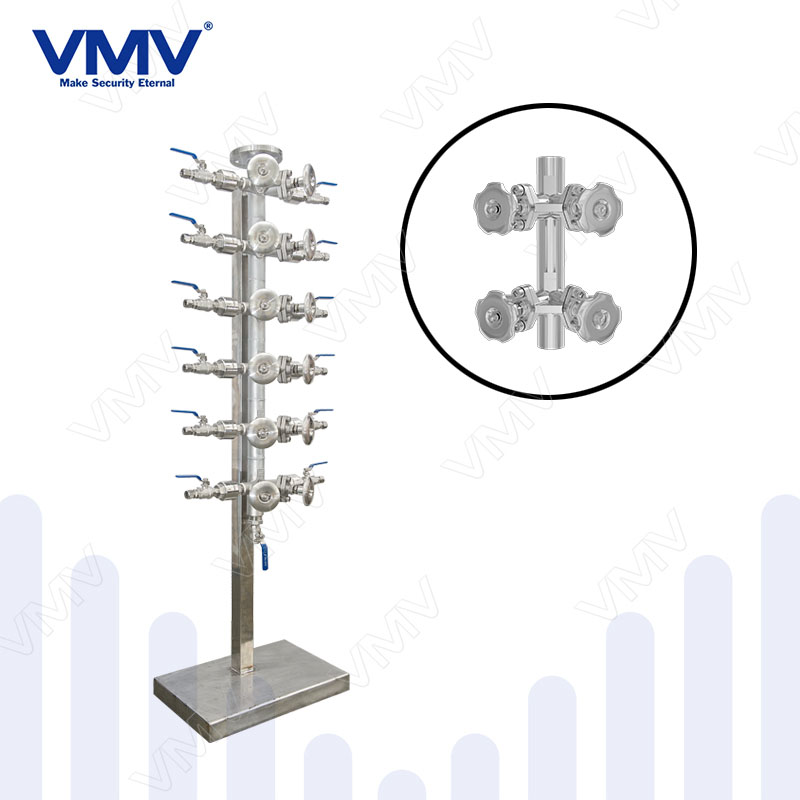

2.Reasonable layout: Adjacent valves are arranged at an angle of 60°, and reasonable pipe bundle valve spacing ensures the installation height of the trap; the connection method is flange, welding, thread, and ferrule.

3.Reliable and durable closing system: integrated design of valve core and stem, using high-hardness martensitic stainless steel to improve erosion resistance; the accuracy of the spherical surface of the valve core can reach micron level, the valve seat is made of martensitic stainless steel, and the sealing surface is cone. Surface, realize the valve core-seat linear sealing closure, improve the sealing performance, and prevent leakage.

4.Outer seal of the valve: The durable stainless steel bellows and graphite packing realize the dual seal design of the valve stem, which eliminates the leakage at the packing and is flexible in opening and closing.

5.Bellows condensate manifolds body: CF8 stainless steel medium temperature wax precision casting, high strength, long life, corrosion resistance, exquisite appearance and compact structure.

6.Handwheel: 304 corrosion resistant stainless steel handwheel, beautiful and exquisite, good grip feeling.

7.Concealed transmission thread: placed inside the handwheel, dust proof and waterproof, Reduce torque.

8Thread compression sleeve: anti-loose structure of the packing thread compression sleeve to avoid loosening. It is made of martensitic stainless steel, which has high hardness and corrosion resistance.